Biology meets engineering

EMBL Hamburg’s Instrumentation team constructs instruments for structural biology research, including a new robot for sample handling

Studying the structure and function of biological molecules a truly interdisciplinary endeavour. At EMBL Hamburg, structural research relies on cooperation between experts in different disciplines, including those in the Instrumentation Team, which consists of physicists, mechanical and software engineers, and robotics experts. Together, they construct diverse instruments for X-ray-based structural biology tailored to the needs of users.

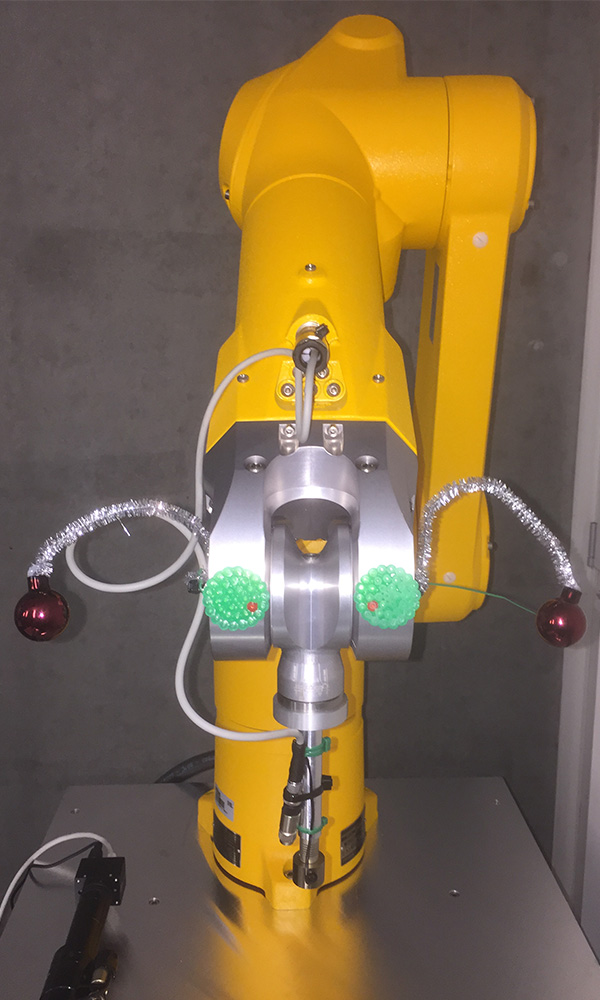

Last year, a new transfer system has joined the MARVIN (MultiAxesRobotic-VersatileINstaller) robot family. The MARVIN system enables the quick and safe handling of fragile crystals, which are used by crystallographers to determine the structure of proteins.

The new MARVIN will accompany another machine, the CrystalDirect™ Harvester, which is already in operation at EMBL Hamburg. The CrystalDirect™ technology consists of an extremely precise robot developed at EMBL Grenoble to automatically harvest protein crystals from CrystalDirect™ crystallisation plates onto tiny metal pins to then preserve them by cryo-cooling. This is far more convenient than handling crystals manually, and can also be done remotely. However, until now, users of the Harvester at EMBL Hamburg had to take the crystal-carrying pins in and out of the machine manually. They then had to place these pins one-by-one into storage containers – also known as pucks – which must be stored in liquid nitrogen at -196°C. During this tedious and time-consuming procedure, the precious samples could be accidentally mixed up, damaged or even lost.

MARVIN makes the process of sample handling easier and faster, but – even more importantly – will enable users to do it remotely, from any place on Earth with internet connection. The robot mounts empty pins into CrystalDirect™ Harvester, then picks crystal-carrying pins up and stores them safely in vials filled with liquid nitrogen. It can even load and unload pucks automatically. The duo – CrystalDirect™ Harvester and MARVIN – will also allow non-expert users to prepare a large number of tricky and tiny protein crystals.

“Like for any other instrument we work on, this was a real team effort. From the very beginning, different members of our team contributed their expertise in robotics, electronics, mechanics, programming and cryogenics,” said Moisés Bueno, software engineer at EMBL Hamburg, who led the programming work on this project. “In addition, we integrated several elements developed by the Instrumentation Team at EMBL Grenoble. The work was challenging because I had to learn many new things, such as image processing. But that was something I really wanted to learn, so it was fun.”

The Instrumentation Team works closely with EMBL Hamburg’s beamline scientists, to make sure the instruments they build meet their needs. MARVIN, for instance, was tested by Saravanan Panneerselvam, Senior Technical Officer in the Schneider Group.

“We are excited to use the robot with complicated and difficult to handle samples, such as crystals formed within living cells,” said Panneerselvam. “Such samples can now be reliably harvested from CrystalDirect™ plates.”

Working as an engineer at EMBL

Bueno has since moved to the European X-ray Free-Electron Laser Facility (European XFEL) to take up a new post as PLC Developer and Support Engineer. European XFEL has a long-standing cooperation with EMBL, including through EIROforum.

“For me, EMBL has been an entrance to the scientific community,” said Bueno. “As an engineer at EMBL, I had the opportunity to work with top notch technologies that in many other places you could only dream of. I also met very clever people from all over the world. All of this was a very enriching experience for me.”

The EMBL Hamburg’s Instrumentation Team established their robotics lab a few years ago to enable projects such as MARVIN.

“The new system is a prerequisite for users to prepare their crystals in the future with the harvester and without the need to travel to Hamburg.” said Stefan Fiedler, the leader of the Instrumentation Team. “We will continue to develop our system in coordination with our colleagues in Grenoble. The MARVIN platform is quite universal so that we can add readily new functionalities and use it also for other applications, like X-ray microscopy for mounting sample on standard supports.”

The new instrument is in fact already the third MARVIN robot at EMBL Hamburg, the other two robots being in use at the beamlines P13 and P14. There, they transfer thousands of pins per year loaded with crystals from storage containers directly onto a diffractometer, an instrument where the crystals are hit by an X-ray beam during an experiment. The measurements at the beamlines can be carried out remotely already, which was an important feature during the pandemic.

Before it began operations, the robot was showcased to the public during an outreach event, Hamburg Night of Science. The engineers programmed the robot such that children and their parents could steer it to fish out hidden crystals and place them in front of a microscope. To get a better view, they could also make the robot rotate the sample. The effort paid off: MARVIN was greeted with a furore at the event, and the preparation was part of essential groundwork for getting the robot ready for its future tasks.

“The activity for the night of science it is something that I am really proud of,” said Bueno. “I brought up the idea and we agreed to bring to the public something that combines instrumentation with crystallisation. Everyone in the team contributed in one way or another.”

The components for the new system were purchased with funds from German Federal Ministry of Education and Research, grant ID 161L0100.