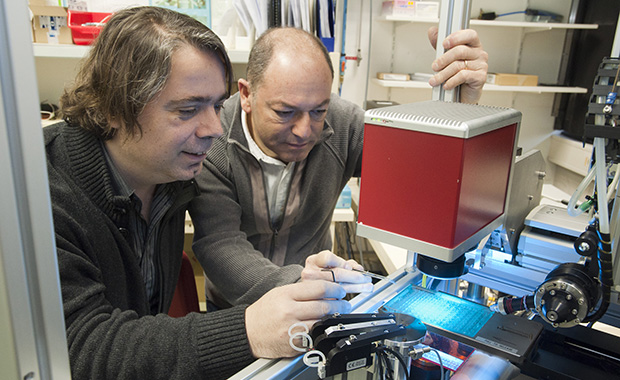

The man behind the machine

Crystallography, one of the approaches used by EMBL scientists to study the internal structure of proteins, is the analysis of distinctive diffraction patterns that are created when X-rays generated at synchrotrons are fired at biomolecules in crystalline form

The technique has helped to reveal the structures of several important molecules including DNA, the ribosome, and the poliovirus. Behind the scenes, it is the ingenuity and craftsmanship of beamline engineers that has helped push forward this field.

EMBL’s Florent Cipriani has dedicated the past few decades of his career to helping molecular biologists to use crystallography. “We aim to help scientists get better quality data more quickly,” says Cipriani, whose team is located on the EPN – European Photon and Neutron – campus in Grenoble. Their innovations range from devices that enable the harvesting of extremely delicate crystals to helping in the analysis of diffraction patterns. “Beyond a passion for technical challenges, our driving force is really to make our beamline users happy,” he says. “I often say the instrumentation lab is in the basement of the EMBL building because we support the science!”

Cipriani’s team is currently commissioning a new sample changer for one of the crystallography beamlines at the European Synchrotron ESRF run by EMBL in order to increase their capacity and to perform experiments more rapidly.

Handle with care

Sample changers take care of the biological material set to enter the X-ray beam. Before shutting the heavy lead door of the experimental hutch protecting them from the intense X-rays, scientists first load their precious frozen samples into a container (known as a Dewar) holding liquid nitrogen. Then, one by one, the samples are moved gently from the icy chamber and placed carefully and precisely into the X-ray beam by a robotic arm, ready for measurements that the scientist controls remotely from the other side of the door.

Automation means things get done quickly, safely, accurately and without the need for any human intervention. However, while producing good quality crystals of small and uniformly shaped proteins is difficult enough, crystallisation of larger and more complex proteins is even more of a challenge, usually producing crystals of poorer quality and smaller size.

“Structural biologists frequently have to screen several hundred tiny crystals before they find any good ones and obtain the high resolution data needed to build atomic 3D structures to answer related biological questions,” explains Cipriani. And with such small delicate crystals with handling really becomes a problem. “One of the last parts of the crystallography experiment that is still manual is moving the crystals from the lab to the beamline,” says Cipriani. “So we started wondering how we can automate this too.”

One of the last parts of the crystallography experiment that is still manual is moving the crystals from the lab to the beamline

Cipriani’s team was one of the teams that developed CrystalDirect™ – an automated crystal harvesting technology. The miniscule, delicate crystals grown in the lab ready for beamline experiments must be painstakingly hooked out of their plates using tiny nylon fishing loops and the naked eye. But working together with Josan Marquez, who leads EMBL’s high-throughput crystallisation laboratory in Grenoble, they developed a method that eliminates crystal handling by growing them on top of a thin film. This can be used directly in the X-ray beam after it is cut with a laser.

The first systems are already working in Grenoble and the first commercial product will be available at EMBL Hamburg in the summer. “Not only is it possible to easily extract single crystals but even entire plates can be put directly into the beamline circumventing the need for any manual handling at all,” Cipriani explains. “The system allows a high level of precision and flexibility and that’s what we always aim for.”

Cipriani is eager to bring these innovations to as many users as possible, and over the years several of his team’s developments have been commercialised and used worldwide. “People seem to appreciate them,” he says, pleased. Crucial to this process is the EMBL’s technology transfer activity, EMBLEM. “It’s sometimes difficult balancing different interests but the global benefit is huge and EMBLEM is a really important partner for opening up discussions with industry.” Next up is a self-cleaning Dewar. “It cleans out the liquid nitrogen, thus preventing ice crystals contaminating and degrading diffraction data,” he says enthusiastically.

Setting the standard

Recognising the fact that scientists tend to visit several synchrotrons to conduct their experiments, Cipriani is also keen to see that equipment is standardised across all sites. He has been designing a new compact and precise sample holder as part of the EC-funded project BioStruct-X, proposed as a future European standard. “The standard we developed 10 years ago proved beneficial for scientists who now regularly visit several synchrotrons,” he explains. “The new standard should also speed up crystal processing while reducing handling and transportation costs,” Cipriani explains.

As scientists look to gain ever more detailed images of ever more complex biomolecules, much rests on the shoulders of beamline engineers. But Cipriani is confident that the flow of ingenious solutions will continue to enable researchers to push the boundaries of structural biology. “With so many projects, what is missing is time!” he adds with a smile. “Above all, good instrumentation is the fruit of the work of diverse people who like working together – what we call a team!” he concludes.