Mirror, mirror

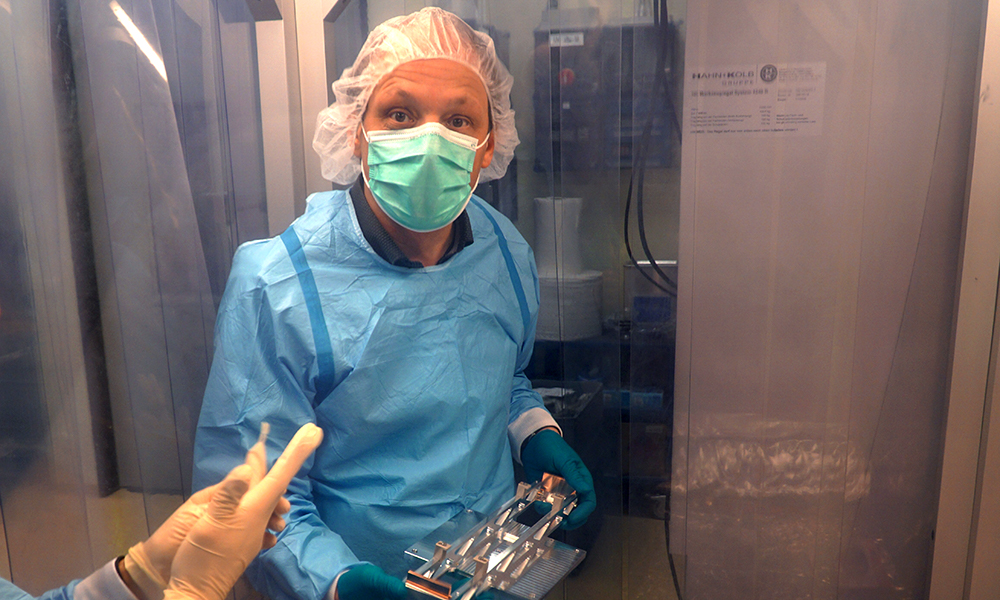

Mirrors are useful not only as household items, but also as scientific tools. Scientists at EMBL Hamburg use specially designed mirrors to reflect and focus X-ray beams onto tiny crystals made of proteins or other biological molecules. By analysing the pattern of X-rays diffracted as they cross the crystals, scientists can determine the molecular structure of the proteins that make up these crystals.

The preparation of an X-ray mirror is a complex process involving a technique called ion beam figuring. In this technique, the mirror is polished to an ideal elliptical shape using a focused beam of plasma (argon ions). This is done with nanometre precision: if you scaled up the mirror to the size of St Peter’s Square in Rome, you would find no deviations from the desired shape bigger than the diameter of a small bacterium.

Each mirror is unique and tailored to its beamline. After each round of polishing, the mirror is shipped to a specialised metrology laboratory, where the shape is measured and compared to the desired surface. Metrologists create a map of differences to be corrected during the next round of polishing with ion beam figuring. The whole process can take more than a year. At each step, even a tiny mistake could spoil the surface, making it necessary to start again from scratch.

Using these mirrors, EMBL’s beamlines can focus X-ray beams much better than before. This allows researchers to use smaller crystals or smaller volumes of precious protein samples, and to obtain higher-quality data. These improvements are exciting news, not only for EMBL scientists but also for hundreds of external users each year, who come to EMBL’s facilities to conduct their experiments.

If you have a stunning picture of your science, your lab or your site, you can submit it here.