EMBL’s Scientific Instrument Maintenance team – helping us achieve a circular economy

In 2022, the European Commission announced the establishment of a ‘right to repair’, with a view to saving costs for consumers and facilitating the development of a circular economy in Europe. A circular economy is an approach to production and consumption which aims to keep products and materials in operation for as long as possible by repairing, reusing, refurbishing, and recycling existing products and resources.

EMBL’s Scientific instrument Maintenance (SIM) team has been repairing, refurbishing, and maintaining EMBL’s scientific equipment for many years, contributing greatly to making EMBL’s operations more circular and more sustainable.

Biomedical research is very resource intensive and requires the heavy use of specialised equipment. EMBL Heidelberg has 30,000 pieces of heavily used equipment, many of which break down or need adjusting during their lifetime. We estimate that the embodied carbon of the instruments and equipment EMBL purchases every year accounts for 17% of our carbon footprint.

However, this figure would inevitably be much higher if we didn’t have the SIM team to repair faulty instruments and keep our existing equipment in operation. SIM receives about 700 repair requests a year from the Heidelberg and Hamburg sites, often involving more than one piece of equipment.

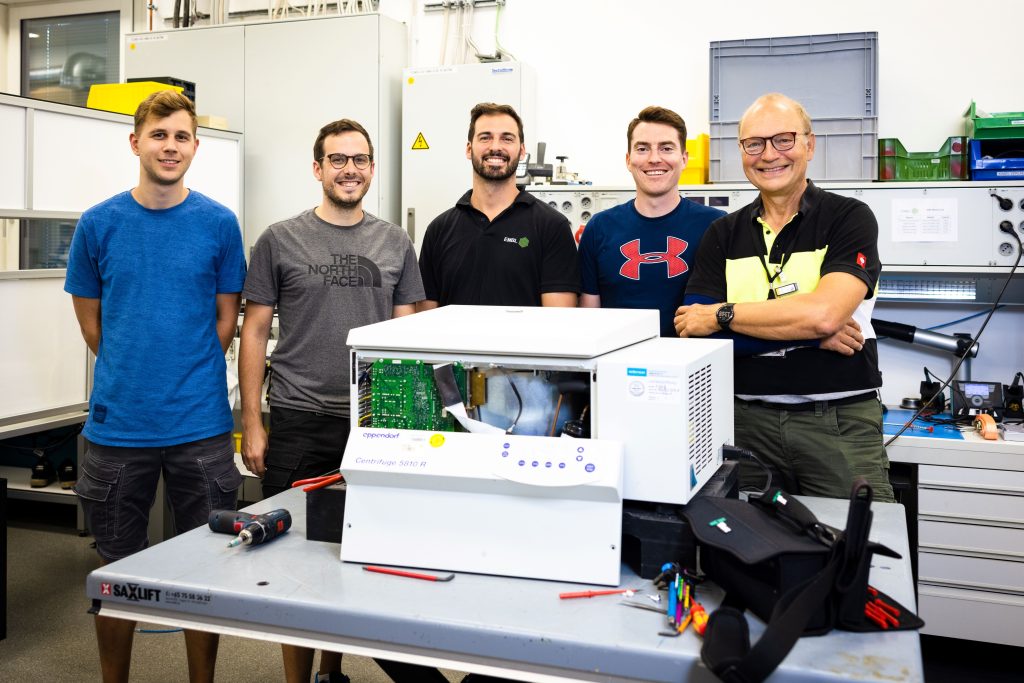

The sustainability team had a conversation with Niklas McPhee, a Maintenance Technician in EMBL’s SIM team, which is made up of five experts and is led by Thomas Heinzmann. During the conversation Niklas demonstrated a real interest in sustainability, (he even installed solar panels at home). But he had not realised how much his work contributes to progressing EMBL’s ambitions for greater sustainability. It also became clear to us that the work SIM does goes far beyond repairing broken equipment .

For example, consider the maintenance of ULT (ultra-low temperature) freezers which can each use as much electricity as an average four-bedroom home. Maintaining these freezers includes replacing the filters, cleaning the heat exchangers, scraping ice from the seals, and replacing broken locks – all of which makes them run more efficiently and protects the valuable samples inside. The SIM team has an alert system which monitors all of EMBL’s ULT freezers and sends alerts to their cell phones when there is a problem, allowing them to respond to any issues within 20 minutes.

Did you know?

A single ULT freezer typically uses the same amount of energy as an average four-bedroom German household, and EMBL has over 70 of them. That’s why we suggest users keep them clean and free of ice, have an inventory of the contents so that the doors need to be opened for as short a period of time as possible, and consider setting them to -70 °C, instead of -80°C, as this alone can save a third of their power use.

When the sustainability team visited the SIM workshop, the SIM team was busy repairing a number of window blinds, replacing the motors so that new blinds wouldn’t need to be purchased. In addition to repairing equipment, the team finds use for equipment that is no longer needed at EMBL. They salvage spare parts from old equipment to repair other devices and help to facilitate the shipment of working but outdated equipment to developing countries or other facilities, using the EMBL-affiliated charity program “Aid for Labs”.

We asked Niklas if there is something scientists can do to facilitate circular economy efforts. “When buying new equipment don’t look only at the price, look at the quality of the device and the possibilities to repair and replace faulty parts,” said Niklas. Some suppliers of lab equipment offer the SIM team repair manuals, spare parts, training, and even remote repair services where a technician explains the repair process step by step through a video call. These services keep products in use and pay off in the long term, even if the products themselves are more expensive initially.

With sustainability in mind, let’s keep Niklas’s advice in mind when purchasing new equipment and taking good care of what we already have. Good maintenance of machines and other appliances is a huge contributor to sustainability and to the goal of a fully circular model in scientific research.